Regularly testing your emergency lighting is not just a box-ticking exercise; it is a fundamental legal requirement for commercial and multi-occupancy properties in the UK. For most systems, this means a brief functional ‘flick test’ every month, followed by a much more thorough full duration test once a year. Adhering to this schedule is the only way to be confident your system will work as intended when the power fails or a fire alarm activates.

This guide is for business owners, landlords, facilities managers, and anyone designated as the ‘Responsible Person’ for fire safety. It explains the required testing frequency, what each test involves, and your legal obligations under UK law.

If you are the ‘Responsible Person’ for a property, understanding your fire safety duties is not optional, it is the law. The responsibility for ensuring people can evacuate safely rests squarely on your shoulders, and emergency lighting is a critical part of any credible fire safety strategy.

This duty is established in the Regulatory Reform (Fire Safety) Order 2005. Specifically, Article 17 states that all fire safety equipment, including emergency lighting, must be “subject to a suitable system of maintenance and are maintained in an efficient state, in efficient working order and in good repair.” This makes routine testing a non-negotiable part of your role.

While the Fire Safety Order tells you that you must maintain your system, it does not specify how often. For that, we turn to BS 5266, the code of practice for the emergency lighting of premises. This standard is considered the authoritative guide.

Following BS 5266 is universally recognised as best practice and is the surest way to demonstrate due diligence if an enforcement authority, such as the local Fire and Rescue Service, inspects your property. Adhering to this standard ensures your testing schedule is robust, logical, and designed to identify faults before they become a danger.

The term ‘Responsible Person’ can be confusing, but it generally refers to whoever has control over the premises. This role typically falls to:

If you fit into any of these categories, you are legally accountable for implementing and recording a suitable testing regime. It is also important to understand the wider legal landscape, including the requirements for a UK Electrical Safety Certificate (EICR), to gain a full picture of your duties.

In the eyes of the law, ignorance is not a defence. A failure to maintain and test life-saving equipment like emergency lighting is viewed as a serious breach of duty, potentially leading to severe penalties.

The consequences of non-compliance can be severe. Enforcement action can begin with informal warnings but may escalate to formal notices that legally compel you to rectify the issues. In the worst-case scenarios, especially where a lack of maintenance is found to have put lives at risk, you could face prosecution, leading to substantial fines or even imprisonment. Beyond the legalities, a faulty system undermines your entire fire safety plan and directly jeopardises the safe escape of occupants during an emergency.

If you are responsible for a building’s safety, you need a structured plan for testing your emergency lighting. Simply flicking the lights on and off occasionally is insufficient and will not satisfy your legal duties. The official guidance, British Standard BS 5266, sets out a clear framework with three distinct types of tests, each with a specific purpose.

Once you understand these different checks, the entire process becomes a logical part of your safety management routine. It is all about building a solid maintenance schedule that identifies problems before they can become critical failures during a real emergency.

The most frequent check is the monthly functional test, often called a ‘flick test’. This is a short, simple procedure designed to confirm that your emergency lights switch on when the mains power is interrupted. Think of it as a quick health check for the entire system.

The test involves simulating a power cut, usually via a dedicated test switch or key, for just long enough to see every emergency light illuminate correctly. This quick check verifies that the system has switched over to its battery backup as intended.

Under BS 5266-1 standards, these monthly tests are a mandatory part of the UK’s fire safety framework. The test is deliberately kept brief to identify obvious faults without significantly draining the batteries, ensuring the system remains ready for a genuine power failure. As explained at allwellpropertyservices.co.uk, this regular check is a cornerstone of compliance, and the Regulatory Reform (Fire Safety) Order 2005 makes it a legal duty for the ‘Responsible Person’ to carry them out and keep detailed records.

While the monthly test confirms the system activates, the annual full duration test is about endurance. This is a much more stringent assessment designed to prove the internal batteries can power the lights for their full rated duration, which for most commercial premises in the UK is three hours.

This test is the ultimate proof of performance. It simulates a prolonged power outage, pushing the system’s batteries to their limits to ensure they hold enough charge to illuminate escape routes for the entire time required for a safe and orderly evacuation.

A successful annual duration test is your primary evidence that the system will not fail halfway through an actual emergency. It is highly effective at identifying older, degraded batteries that might pass a brief ‘flick test’ but would fail when needed most.

During this three-hour test, every light is monitored. If any fitting fails before the full period has elapsed, its battery pack or the entire unit must be replaced promptly. This is not just a compliance task; it is critical for protecting lives.

Alongside hands-on tests, simple visual inspections play an important role, especially for systems running from a central battery. These checks are straightforward and can be incorporated into daily or weekly building management routines with minimal disruption.

The purpose is to spot obvious physical problems before they affect the system’s operation. You are looking for:

These simple walkaround checks are your first line of defence, catching minor issues that might otherwise go unnoticed until the next formal test.

To keep your emergency lighting system reliable and compliant, a consistent testing schedule is not just a good idea; it is non-negotiable. Sticking to a proper routine removes the guesswork from your legal duties and turns them into simple, manageable tasks. The primary guidance here is British Standard BS 5266, which provides a clear framework broken down into daily, monthly, and annual checks.

Following this schedule is the single best way for a Responsible Person to demonstrate they have exercised due diligence. It ensures that any potential faults, from a dying battery to a failed lamp, are identified and rectified long before they can become a problem during a real emergency. Consider this routine the backbone of your fire safety management plan.

If your building uses a central battery system to power its emergency lights, a quick daily visual check is required. This is not an intensive technical test; it is a simple walkthrough to confirm the system is operational.

The main focus is the central power unit itself. You just need to glance at the indicator panel to ensure there are no fault lights displayed and that it shows a healthy, charging status. It only takes a moment but can provide a crucial early warning if something is beginning to go wrong with the main power supply.

Every emergency lighting system, regardless of type, requires a monthly functional test. Often called a ‘flick test’, this is a short, simulated power cut designed to prove that every emergency light fitting works correctly.

The process is straightforward: you interrupt the mains power to the lighting circuit using a dedicated test key or switch. Once you have done that, you must walk the escape routes and visually check that every single emergency light and illuminated sign switches on as expected. The test itself should be brief; a few minutes is sufficient to check everything is working without excessively draining the batteries.

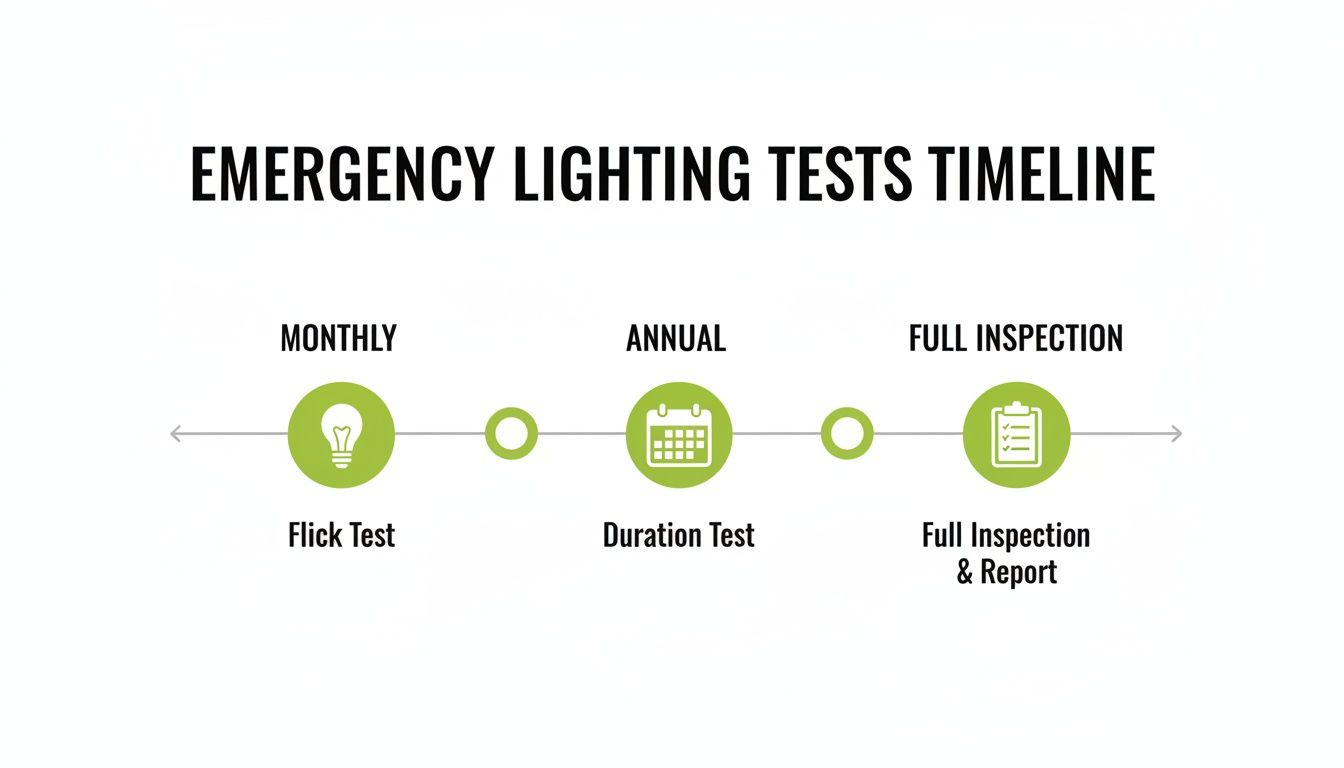

The timeline below gives a clear picture of the key milestones in a compliant testing schedule, from the quick monthly flick test to the much more thorough annual duration assessment.

This visual guide reinforces the importance of a structured, year-round approach to maintenance, ensuring no critical checks are missed.

To help you keep track, here is a quick summary of what is expected.

This table breaks down the minimum testing frequencies for emergency lighting systems, as recommended by British Standard BS 5266-1. It outlines who is typically responsible for each check, helping you to delegate tasks effectively.

| Test Type | Frequency | What to Check | Responsibility |

|---|---|---|---|

| Visual Check (Central Systems) | Daily | Check central unit for fault indicators and healthy charging status. | On-site staff or Responsible Person |

| Monthly ‘Flick’ Test | Monthly | Simulate a mains failure to ensure all lights activate correctly. | On-site staff or Responsible Person |

| Annual Duration Test | Annually | Run a full 3-hour discharge test to check battery longevity. | Competent Person (e.g., qualified electrician) |

Following this schedule is the most reliable way to demonstrate compliance and ensure your system is always ready for an emergency.

The most important and rigorous check in your schedule is the annual full duration test. This is what proves your system’s batteries can power the emergency lights for their full rated duration, which is typically three hours for most UK commercial buildings.

This is an endurance test. The mains power is switched off, and the system is left to run on its battery backup for the full three hours. Throughout this period, every light fitting must remain illuminated. Any light that fails, dims significantly, or cuts out before the three hours are up has failed the test and needs to be repaired or replaced immediately.

To get this right, it helps to have clear Standard Operating Procedures for electrical maintenance. A successful annual test is the only real proof that your system will perform its function during a prolonged power cut. You can learn more by reading our detailed overview of the core https://hmofiriskassessment.com/emergency-lighting-testing-requirements/.

Remember, the purpose of this schedule is not just about ticking boxes for an inspector. It is a fundamental safety process designed to ensure that when the lights go out for real, your emergency system performs, protecting lives by illuminating the way to safety.

In fire safety, there is a simple but critical rule: if it is not recorded, it did not happen.

From a fire safety inspector’s perspective, meticulous records are as crucial as the tests themselves. A detailed emergency lighting logbook is not just good practice; it is your primary evidence of due diligence and a legal requirement under the Fire Safety Order 2005.

These records serve a practical purpose beyond mere compliance. They create a vital historical account of your system’s performance, helping you track battery health, identify recurring faults in specific lights, and schedule proactive maintenance before a minor issue becomes a critical failure. A well-maintained logbook demonstrates a systematic approach to fire safety, which builds trust with enforcement authorities.

This documentation is your first line of defence during an inspection or in the unfortunate event of an incident. It proves you have a structured maintenance plan and are actively fulfilling your duties as the Responsible Person.

A compliant emergency lighting logbook needs to be more than just a list of dates. To be effective and satisfy an inspector, it must contain specific, detailed information for every test. Vague entries like “monthly test done” are not sufficient and will almost certainly be flagged as inadequate during an audit.

Your records must clearly detail the who, what, when, and where of each test. This level of detail is essential for tracing faults and proving that a thorough check was completed.

To meet the requirements of BS 5266, your logbook should capture the following for every test:

Creating a logbook does not need to be complicated. A simple table, whether in a physical book kept on-site or a digital spreadsheet, can work perfectly. The key is consistency and ensuring all necessary fields are filled in accurately after every test.

Here is a straightforward template you can adapt for your premises.

| Test Date | Test Type (Monthly/Annual) | Luminaire ID / Location | Pass / Fail | Fault Details | Corrective Action & Date | Tested By (Name/Signature) |

|---|---|---|---|---|---|---|

| 01/07/2024 | Monthly Functional | All Fittings | See Notes | EL-07 (Office 2) Failed | Battery pack replaced 02/07/24 | J. Smith |

| 01/08/2024 | Monthly Functional | All Fittings | Pass | N/A | N/A | J. Smith |

| 15/09/2024 | Annual Duration | All Fittings | See Notes | EL-12 (Corridor) Failed at 2hrs | Unit replaced 16/09/24 | P. Jones (Elec.) |

An incomplete or poorly maintained logbook can be interpreted by an inspector as a sign of a wider failure in fire safety management. They will rightly assume that if the paperwork is disorganised, the physical maintenance is likely to be just as neglected.

The method you use to keep records is less important than the quality of the information itself. Both traditional paper logbooks and digital systems have their merits, and the best choice often depends on the scale and complexity of your property portfolio.

A paper-based logbook, often a dedicated binder kept in a central, accessible location like a reception desk or plant room, is simple and effective for many smaller businesses. Its physical presence makes it easy to find during an inspection. The downside is that it can be lost, damaged, or become illegible over time.

Digital records, such as spreadsheets or specialised compliance software, offer significant advantages, particularly for anyone managing multiple properties. They are easily searchable, can be backed up securely, and allow for quick sharing with contractors or inspectors. Digital systems also make it easier to track trends and schedule future maintenance, ensuring nothing is missed.

Whichever system you choose, the priority is to keep it organised, up-to-date, and readily available for inspection at any time.

Even with the most diligent testing schedule, you will encounter faults. That is the entire point of checking your system regularly: to identify minor problems before they become critical safety risks during a real emergency.

Knowing what typically goes wrong helps you troubleshoot much faster. Most issues come down to a few common culprits: depleted batteries, failed lamps, or physical damage to the light fittings themselves. Spotting these early means you can get them rectified quickly, keeping your system compliant and, more importantly, ready to protect lives.

By far, the most common failure identified during an annual duration test is a depleted battery. The battery pack is the heart of every self-contained emergency light, and just like the battery in your phone, it has a limited lifespan, typically around four years.

You will often see a light pass the short monthly ‘flick test’ without issue, only to fail an hour into the full three-hour test. This is the classic sign of a degraded battery that can no longer hold sufficient charge.

If a light fails during a full test, the battery is almost certainly the cause and will need replacing by a competent person. It does not necessarily mean the whole fitting is broken. A good practice is to note down battery replacement dates in your logbook so you can anticipate when they are likely to need replacing.

While modern LEDs are much more robust than older fluorescent tubes, they do not last forever. A lamp failure is usually obvious during the monthly functional check: the light simply will not switch on when you interrupt the power.

With older fluorescent systems, a flickering or dim glow is a clear indicator that the tube needs changing. For modern integrated LED units, a failure usually means the entire fitting has to be replaced, as the LED components cannot normally be swapped out.

Physical damage is another frequent issue, especially in busy corridors, warehouses, or public areas where fittings can be accidentally knocked. A cracked diffuser not only looks untidy but also reduces light output and allows dust and moisture to enter, which can damage the internal components.

It is also crucial to check that your signs are not blocked. A perfectly working emergency exit sign is useless if someone has placed a new poster over it, positioned a tall plant in front of it, or stacked boxes beneath it. Part of any good test is a simple visual walk-through to ensure every light and sign is clearly visible along the entire escape route.

A compliant emergency lighting system is about more than just function; it is about visibility and direction. An obscured sign can cause fatal confusion during an evacuation, making a simple visual check as important as the technical test itself.

When you find a fault, the key is to act promptly. A simple fix like changing a fluorescent tube might be handled in-house. However, for anything involving battery replacements or circuit faults, it is vital to use a professional. For more on the legal importance of a fully working system, you can find detailed guidance on emergency lighting fire safety.

Always remember to record the fault and the corrective action in your logbook. This closes the loop and proves you are actively maintaining a safe, compliant building.

As the Responsible Person, one of the key decisions you will make is whether to handle your emergency lighting tests in-house or engage a specialist contractor. There is no single correct answer. The best approach depends entirely on your circumstances, including the size and complexity of your building, and the competence and time you have available.

Making an informed choice is vital for keeping up with the required emergency lighting testing frequency. A rushed or poorly performed test is as bad as a missed one, so it is crucial to be realistic about what you can manage internally.

Managing tests internally gives you immediate oversight and can appear cheaper on the surface. This approach often works well for smaller, simpler properties where a facilities manager or a trained member of staff can confidently handle the monthly flick tests.

However, this approach comes with significant responsibilities. You must be certain that the person conducting the tests is genuinely competent, has received appropriate training, and knows exactly what to look for and how to record it. Time is also a major factor; they need sufficient time to do the job properly, without it being neglected due to other duties.

Before committing to in-house testing, ask yourself:

Hiring a competent, third-party contractor provides peace of mind and is a reliable route to compliance. These experts bring specialist knowledge, use calibrated testing equipment, and are efficient at testing all types of systems, from a small office to a large residential block.

An external contractor provides an unbiased, professional verdict on your system’s condition. Their detailed reports are powerful evidence of due diligence, which helps to satisfy inspectors and insurers. While it comes with a direct cost, it often proves more cost-effective in the long run by identifying minor faults before they escalate into expensive system failures.

Even if you handle monthly checks yourself, it is highly recommended to outsource the annual full duration test. This is a critical, complex test that demands a level of expertise and time commitment that is often beyond the capacity of internal staff.

The best choice boils down to a realistic assessment of your resources, the size of your property, and the complexity of your emergency lighting system. A small business with only a handful of emergency lights might find monthly in-house checks perfectly manageable. On the other hand, a landlord of a large HMO or a manager of a multi-storey office block will almost certainly find professional expertise invaluable.

This table breaks down the key factors to help you decide.

| Factor | Best Suited for In-House Testing | Best Suited for Outsourced Testing |

|---|---|---|

| System Complexity | Simple, self-contained units in a small area. | Large, complex systems, or central battery units. |

| Property Size | Small single-site premises (e.g., small shop, office). | Large sites, multi-storey buildings, or multiple properties. |

| Internal Resources | Dedicated, trained staff with available time. | Limited staff, no trained personnel, or high staff turnover. |

| Compliance Confidence | You are confident in your team’s ability to meet standards. | You require third-party verification and detailed reporting. |

Ultimately, your legal duty is to ensure the tests are completed correctly and on schedule. Whether you do that yourself or hire a professional, the end goal is the same: a compliant, fully operational life-safety system that you can rely on.

We have covered the main requirements for testing your emergency lights, but practical, day-to-day questions often arise for property managers and business owners. Let’s clarify a few common points of confusion.

The full duration test itself must run for the system’s rated period, which is almost always three hours in the UK. However, this is not the total time an engineer will be on site.

The entire process is longer. A competent engineer will also need to visually inspect every fitting, properly record all the results, and then safely restore the power and ensure the batteries are recharging. It is a thorough job, not just a flick of a switch.

For the short monthly functional check, yes, you or a trained member of staff can usually handle it, provided you are competent. This means you need to know how to operate the test switch without causing any issues and, just as importantly, what you are looking for, such as a flickering bulb or a light that fails to illuminate.

However, the annual duration test is a different matter. This should always be undertaken by a qualified and experienced person, such as a BAFE-accredited fire safety technician or a certified electrician. It is a much more involved test and is the one that truly proves your system is compliant and fit for purpose.

If any light fails, whether during a quick monthly check or the full annual test, it needs to be repaired or replaced urgently. A failed emergency light represents a serious weakness in your fire safety provisions.

You must meticulously record the fault in your fire safety logbook, along with the date and the exact action taken to rectify it. This creates a clear audit trail and demonstrates that you are managing your responsibilities effectively.

No, the testing frequency is exactly the same, regardless of the technology the lights use. While it is true that modern LED fittings are generally more reliable and have a longer lifespan than older fluorescent tubes, their internal batteries still degrade over time.

The monthly and annual testing schedule set out in BS 5266 applies to all types of emergency lighting. The goal is to ensure the entire system, including the light source, the battery, and the circuitry, is ready to perform when it matters most.

Ensuring your emergency lighting is regularly tested and properly maintained is not just good practice; it is a critical part of your legal duties as a Responsible Person. If you need expert assistance with your fire safety compliance, Fire Risk One provides comprehensive fire risk assessments and professional safety advice across the UK.

Visit our HMO Fire Risk Assessment services page to book your assessment and ensure your property is safe, compliant, and prepared for any eventuality.

Regularly testing your emergency lighting is not just a box-ticking exercise; it is a fundamental legal requirement for commercial and multi-occupancy properties in the UK....

UK fire safety law does not specify a rigid, set-in-stone timetable for fire risk assessments. Instead, it requires your assessment to be kept ‘suitable and...